Predictive Vision for Logistics

Continuous learning, intelligent control

Main features

- Why Predictive Vision?

Predictive Vision for Logistics provides valuable insights into the condition of freight at an early stage, improves process planning, optimizes the use of downstream systems (e.g. scales, APACHE), prevents disruptions in the material flow and adapts flexibly to any logistics requirement thanks to adaptive AI technology.

- Artificial intelligence with an industry focus

A specially developed, self-trained neural network that is fully focused on analyzing logistics environments. The AI is validated, data-secure and highly specialized for the requirements of the transport and logistics industry.

- High-performance in real time

Our AI processes image data in real time - even with multiple cameras simultaneously. The result: lightning-fast analysis, seamless system integration and an immediate response to process deviations.

- Individual & scalable

Whether on-premise or as a cloud solution - the system can be flexibly integrated into your infrastructure. Our AI is highly customizable, multi-client capable and tailored to your individual requirements - for maximum process efficiency and future-proofing.

- Real-time analysis of logistics processes

Predictive Vision interprets and classifies logistical flows of goods as soon as they are recorded. Supported by advanced master data, precise predictions and early intervention options are created, e.g. in the event of excess dimensions or unstable freight. This makes the digital transformation measurable - with real insights and high data quality.

- Flexible detector logic for every application

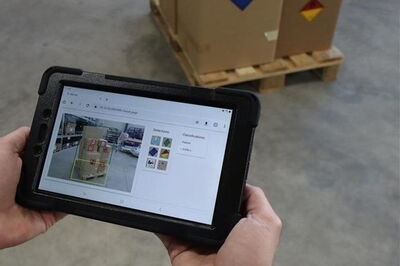

Predictive Vision can be used in a variety of ways and adapted to different logistics environments. Whether in incoming goods, shipping or interim storage - the system reliably detects, analyzes and classifies objects based on visual characteristics. Both dedicated cameras can be installed and existing camera infrastructures can be used. This flexibility enables the automatic detection and classification of pallet types (e.g. EPAL, EUR, IPPC), the precise localization of freight on or next to load carriers, the counting of individual objects and the identification and type classification of dangerous goods labels. All of this is done in real time - fully automated, with high performance and precisely tailored to the requirements of modern logistics processes.

- Advanced detectors based on freight detection

Building on standard detection, Predictive Vision offers a detailed analysis of the freight geometry and surface structure. The system detects whether an object is cubic or irregularly shaped, identifies protrusions on pallets and analyzes stackability based on visual features such as shape progressions and edges. The presence of stretch film or other packaging materials is also detected and taken into account. On this basis, the freight volume including length, width and height can be reliably estimated - a valuable basis for packaging optimization, storage space planning and freight-related calculations.

- Optional: on-premise or cloud - you decide

Predictive Vision is available as an on-premise installation on your own hardware as well as a scalable cloud solution that can be updated at any time. Both variants use a shared, continuously developed model knowledge.

- Optional: image and metadata

The underlying image and metadata are strictly separated, completely anonymized and partially augmented in order to continuously improve the system - without compromising on data protection or information security. This allows companies to benefit from a learning, future-proof AI that can be seamlessly integrated into existing processes - reliably, transparently and with maximum customization.

The continuous analysis and evaluation of freight image data from our 3D freight measurement systems creates valid predictive intelligence. The smart system classifies freight objects early on in the shipping process and detects potential disruptions or deviations before they occur.

Thanks to deep learning and industrial image processing, freight characteristics are automatically detected - e.g. instability, oversize or incorrect labeling.

The result: better control of inspection processes, early quality assurance and more efficient logistics processes thanks to predictive data analysis.

Predictive Vision for Logistics uses advanced image processing and deep learning to analyze freight images in real time. The system detects potential disruptions at an early stage, precisely classifies freight characteristics and provides valid forecast data for your logistics processes. The combination of industrial image processing, object recognition and object classification optimizes the control of checkpoints, shipping processes and downstream systems. The solution not only supports automated freight measurement, but also increases process reliability, improves master data collection and enables targeted warehouse optimization as well as more precise measurement of volume and weight.

The result: efficient use of resources, reduced error rates and sustainably optimized logistics processes - data-based, adaptive and future-proof.

Ready to revolutionize your logistics?

Our experts are available around the clock.